Introduction

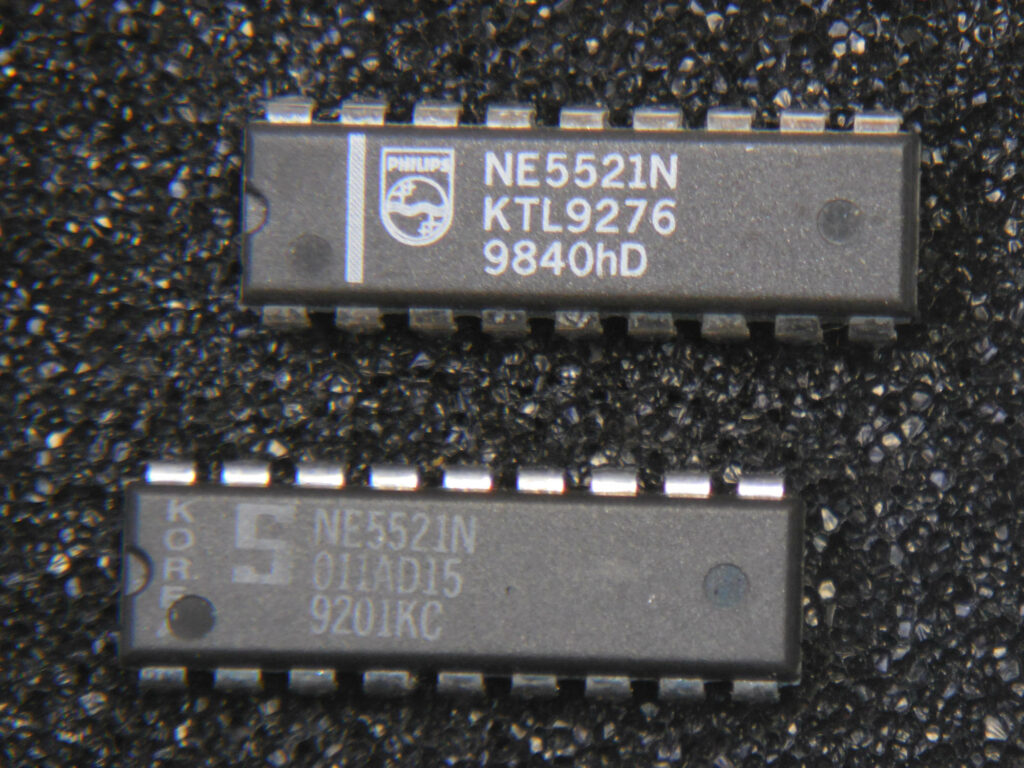

In the world of electronics, supply chain disruptions can have far-reaching consequences. In our case, it was with the NE5521/SA5521. This chip was pivotal to all our electronic measuring tools, starting with the Concentricity Alignment Tool (CAT) line which replaced GE’s own Electronic Radial Alignment Gage (ERAG). It was introduced in 1987 by Signetics (under the Philips name, and now NXP) and provided an oscillator and demodulator for, among other devices, the Linear Variable Differential Transformers (LVDTs) we use.

The NE5521 Disappears in 2008

Our first hint to any issue was when suppliers had dwindling inventory starting in 2008. By by the 4th quarter of that year, the few chips that remained were in the hands of third-party sellers for over $100 each—20 times the price just a year prior.

At that time, one of our regular suppliers told us there had been a fire that destroyed the masks to make the chips. Philips opted to not make new masks, presumably because they were such a niche product. This particular shortage has faded from collective memory, only mentioned in an article by Fierce Electronics on August 1, 2008 which casually notes that the “Philips NE5521 has been recently discontinued”. Historically, it was overshadowed by the Philips plant fire in Albuquerque, New Mexico on March 17, 2000—a fire which didn’t cause much damage to the plant, but it disrupted supplies to cell-phone manufacturers, and has ironically became a classic case study on the impacts of supply chain disruptions.

Moving Forward

The lessons learned from this experience were invaluable. As we scrambled to develop a reliable replacement circuit, we recognized the importance of building in flexibility of component selection. By using more widely available general-purpose components, we could better insulate our products from the whims of the supply chain. Our latest designs are grounded in these principles, and we also buffer our supplies to prevent a repeat of 2008.

![]()