When your turbine needs maintenance, our Concentricity Alignment Tool (CAT) is exactly what you need. It significantly reduces your repair outage time since you do not remove the rotor to perform a realignment. Often referred to as an Electronic Radial Alignment Gauge (ERAG), we are the exclusive manufacturer of these tools.

Our ERAG Features

- Replaces tightwire and laser alignment

- Directly measures the amount of diaphragm misalignment with the rotor in place

- Factory and field-tested method of diaphragm alignment since 1992

- Alignment method proven thru thousands of hours of use

- Depending on the turbine, adjustments can be made and final measurements taken, without having to remove the rotor

- Cost effective — often pays for itself in a single outage

- Easy to use — direct numeric readout in mils (0.001 inch)

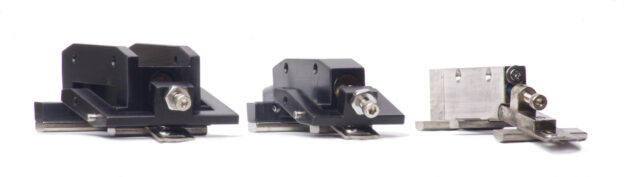

- Accommodates a wide range of turbine sizes

- Very accurate (resolution to 0.0001 inch, accuracy of ±0.001 inch maximum)

- Durable — units rarely require maintenance even after years of service

- Parts are readily obtained from the factory and wearable parts are field replaceable

- See how to use the CAT tool

Basics of Operation

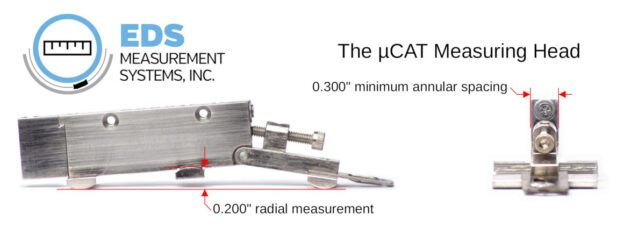

Inserted into the empty packing groove, the Concentricity Alignment Tool (CAT) allows annular space variations to be measured live on a display as it is pulled through the packing groove. The head “rub bars” ride on the turbine shaft and the head lever arm rides on the inner diameter of the diaphragm. As the head is pulled through the packing groove, the lever arm follows the contour of the diaphragm I.D. and the dimensional variation is displayed.

![]()