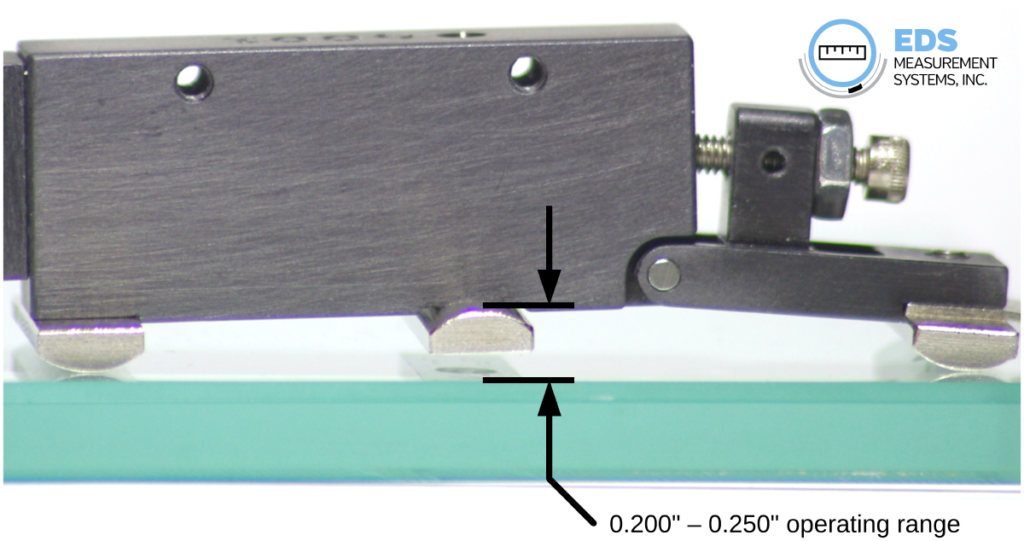

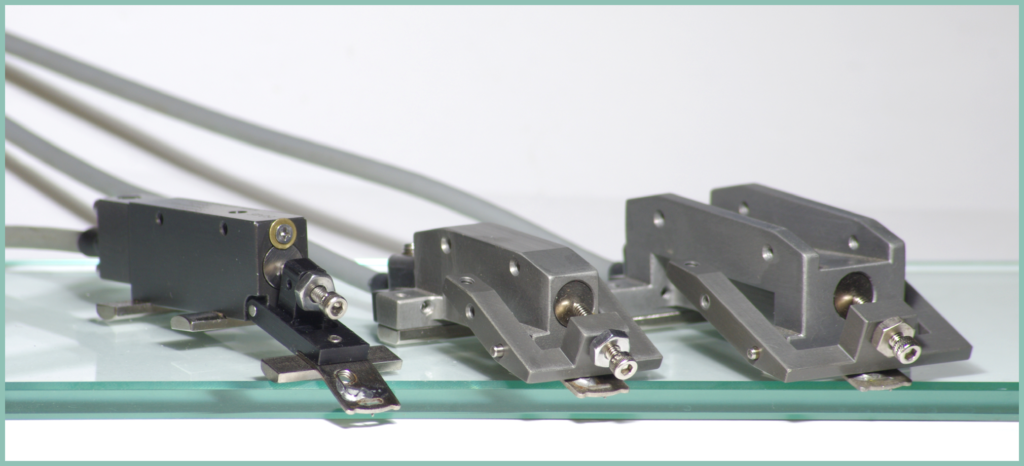

While our SCAT and LCAT measuring heads can be used with a wide range of turbine brush-seal grooves, the latest µCAT ("mu-CAT" or "micro CAT") fits where the others can't. The latest turbines for power generation being developed include stages with very small radial clearance. The µCAT can fit in the same width slot as the SCAT (0.500") and measure radial clearances from 0.200" to 0.250".

We have replaced this model with one that fits brush-seal grooves as narrow as 0.300". Look for an update soon.

Please contact us for information about purchase or rental of this new tool.

![]()